Shumai is a very popular special snack. Use unfermented dough to make skin, top is not sealed. At present, there are two kinds of shumai maker machine on the market, automatic shumai machine and semi-automatic shumai machine.

First of all, let’s take a look at the difference between the two.

Models of shumai maker machine

1. Automatic shumai machine

Automatic shumai machine use flour and stuffing as raw materials to automatically pressing dough, stuffing and forming. No need to make the flour straps specially, just put the well-kneaded dough and stuffing into the appointed place, then start up the machine, it will make the flour straps, pressing dough, dragging and cutting to wrapper, stuffing and forming automatically, finally send the shumai onto the conveyor.

2. Semi-automatic shumai machine

The working principle of semi-automatic shumai machine is mainly due to the dough skin. Semi-automatic shumai machine need to be self-made.

By comparing the working principle of the two, we can find that the semi-automatic shumai machine has lower capacity. So full-automatic shuami machine is the best choice for food factories.

Structure of shumai maker Machine

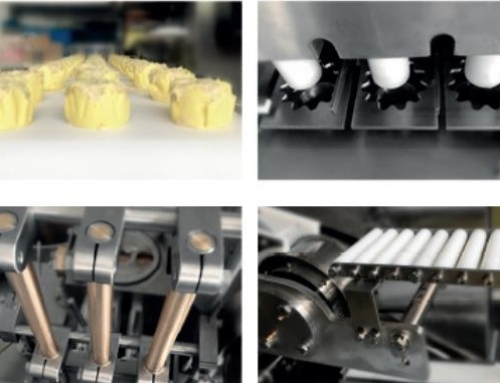

On the whole, both automatic and semi-automatic shumai machine work in the same way. For automatic shumai machine It have five parts, stuffing system, dough pressing system, forming system, main control panel and electric box. Because semi-automatic shumai machine do not need to make dough skin, there is no dough pressing system.

Shumai manufacturing process

After placing the dough and stuffing into the hopper by the automatic shumai machine. The dough is automatically delivered to the forming equipment through the dough pressing system. The stuffing is transferred to the forming equipment through the hopper. When shuami took shape, through the turntable pushes it out to convey. Thus completing the whole production process.

As for the semi-automatic shumai machine. The dough skin is placed directly on the turntable, and the stuffing is pushed into the turntable by the Stuffing push rod holder and wrapped together with the skin, and forming with the dough.

Capacity of shumai maker machine

There are many kinds of shumai machine on the market. It are divided into single row, double row and three rows, and their production capacity is also different. For example, the capacity of double row automatic shumai machine can reach 5000-6000 pieces per hour. The capacity of semi-automatic shumai is much lower, with a single row of about 1000 pieces per hour and a double row of only 2500-3000 pieces an hour. So, the production capacity is a standard when we choose it.

The material of a shumai maker machine

Stainless steel is the main material of food machine. However, stainless steel also uses different models. 304 is a kind of universal stainless steel, It has good corrosion resistance, heat resistance, low temperature strength and mechanical properties. Most shumai machine use this type of steel, which is also an important indicator of the choice of shumai machine.

Shumai maker machine repairing and maintenance

In the production process, the machine will inevitably fail and the loss of parts. Therefore, the repair and maintenance of shumai machine is an indispensable work for us. Regular maintenance can prolong the service life of the machine and is very helpful to the operation and use of the machine.

Conclusion

In the current environment, the traditional manual technology can’t meet the needs of enterprises. Machine manufacturing is more efficient and cost-effective. I believe it will bring faster, more convenient and more efficient mode of production to food enterprises.