Shumai/siomai machine repair and maintenance is an important department in shumai/siomai production. As we know, shumai/siomai machine is based on dough and stuffing as raw materials to achieve automatic dough pressing, stuffing and forming. Through automatic production, thus improving the efficiency of processing.

However, as long as it is a machine, it may fail and repair is necessary. In addition, in order to make the machine run smoothly in the future production, extend the service life, maintenance is also an important work.

So, how to maintain shumai/siomai machine properly, we will discuss this in a few ways.

Name of each part of the shumai/siomai machine

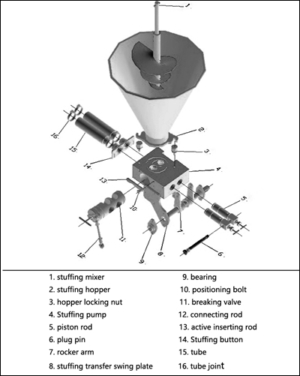

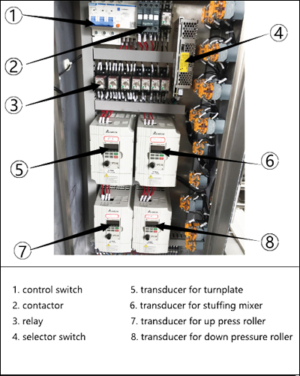

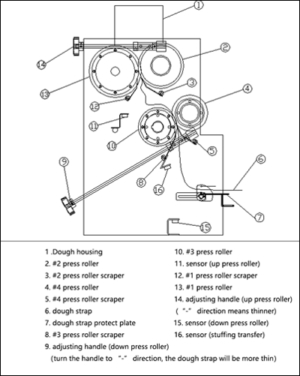

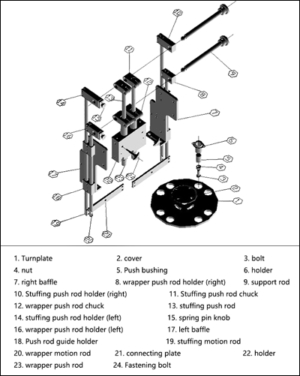

First of all, let us know about the names of basic parts of shumai/siomai machine , this will help us a lot with shumai/siomai machine repair and maintenance in future production. Here I use graphics to describe the machine parts. Our shumai/siomai machine mainly consists of 5 parts: stuffing system, electrical box, master control panel, dough pressing system and forming system.

1. Stuffing system

2. Electrical box

3. Master control panel

4. Dough pressing system

5. Forming system

Dismounting & installation steps

As mentioned earlier, in order to keep the hopper and other parts clean during shumai/siomai machine repair and maintenance, it must be cleaned regularly. However, some components should be cleaned under disassembly conditions, such as stuffing systems. Because it has been in contact with the stuffing for a long time, some residue will be left in the machine, which will affect the hygiene of the product. In order to ensure the hygienic standard of shumai/siomai and the disassembly of stuffing system, we should know something about it. The following is mainly about the stuffing system and the dough pressing system, with specific reference to the figure above.

- Rotating the stuffing mixer clockwise, then pull up the connecting bush to keep the connecting bush and stuffing mixer separate, and then take out the mixer.

- Loosing these two nuts as showing in photo, rotating the hopper anti-clockwise, and then remove the hopper.

- Pull out the plug pin, then pull out these two piston rods from stuffing pump.

- Take the wrench to loose that one bolt in the breaking valve as show in photo.

- Draw back the active insertion rod to keep it separate with breaking valve, and then pull out the breaking valve.

- Pull the spring pin knob, pull out the support rod, and then pull upward the two of stuffing push rod chucks and two of stuffing push rods in turn.

- Pull the spring pin knob, pull out the support rod, and then pull upward the two of wrapper push rod chucks and two of wrapper push rods in turn.

- Loosing the fastening bolts in the holder, then take out the stuffing transfer tube.

- Rotating the manual crank clockwise by hand, then take out the eight of push bushing in turn.

Machine fault exclusion

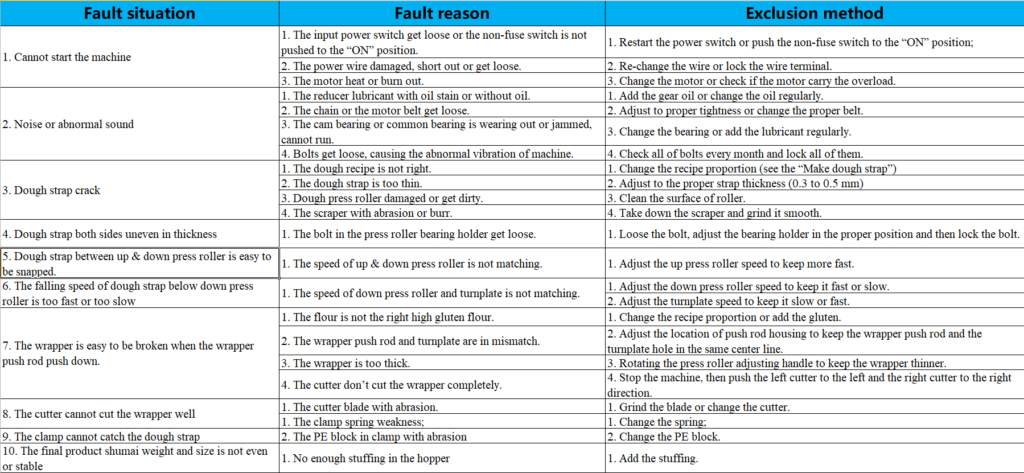

It is inevitable that some failures will occur in the use of the shumai/siomai machine. What should we do when there is a failure? What is the cause of the failure? How should we solve the problem? These are the problems we often encounter in shumai/siomai repair and maintenance. I will talk about the cause of the failure and some solutions in three parts, which I hope will be helpful to you.

Machine maintenance

Regular machine maintenance can make the machine run more smoothly. Below I list some maintenance measures, you can refer to the following methods to maintain shumai/siomai machine.

- Change the oil of the reducer every three month in regular.

- Check the machine inner locking bolts & nuts if get loosing every month in regular.

- Add the grease on the oil injection nozzle every two weeks.

- Check the machine inner cam bearing if get loosing every month in regular.

- Shut off the power before maintenance, and using the proper lubricating oil and tools to assemble and disassemble.

- Check the reducer belt if get loosing or broken every half year, and then adjust or change the belt if necessary.

- Keep clean around the machine, make sure avoid the dust, insect or mouse to break the electrical components to causing danger.

Conclusion

Overall, shumai/siomai machine repair and maintenance is not very difficult. A simple method of operation provides us with a lot of convenience. I hope that these methods can provide help to the production of enterprises.

Check different models of our Shumai/Siomai machine at: SFT-60 Semi-automatic Siewmai Maker Machine, SFT-80 Automatic Two Rows Shumai Machine, and SFT-880 Automatic Three Rows Shumai Maker Machine.