As mochi ice cream’s popularity is on the rise globally, producers need to make more in higher volumes without compromising on the quality even once. Some of the equipment supporting mass-level, day-to-day manufacturing includes the tunnel blast freezer. Freezing small pieces of mochi one by one and in bulk at a high speed and evenly, the machines facilitate a chewy outside and creamy inside that fanatics relish.

In this article, the use of tunnel blast freezers in manufacturing mochi ice cream, how they are categorized, and how they influence all aspects of factory space planning with cold chain logistics are discussed.

1. What Is a Mochi Ice Cream Tunnel Blast Freezer?

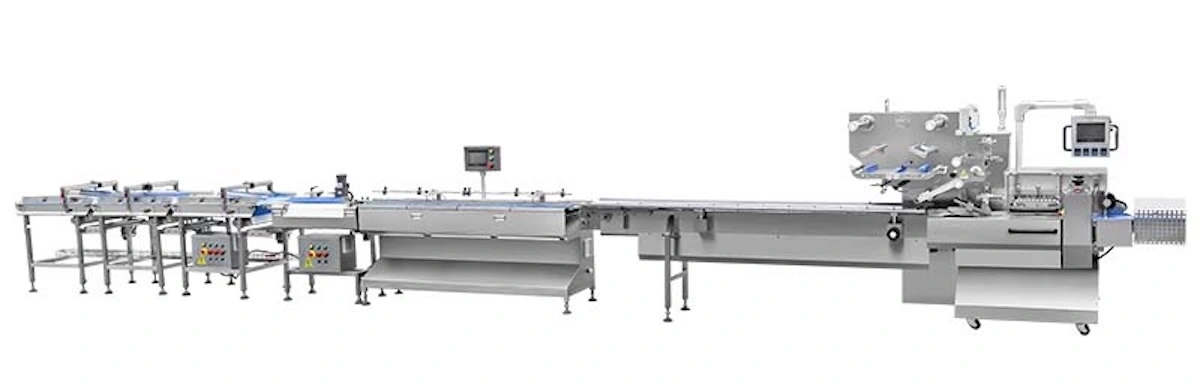

Mochi ice cream tunnel blast freezer is a high-capacity cold air continuous high-speed freeze system, whereby mochi ice cream products are frozen at high speed while in linear motion within a tunnel on a conveyor system. Fixed freezers or chest-type freezers are different from the tunnel blast freezers, and these are best suited for high-throughput applications where hundreds or thousands of pieces are usually frozen within a short duration.

In general, the preparation of the mochi is very crucial. The rice paste used in the development of the mochi crust is a function of temperature. Slowly frozen, it becomes hardened or brittle; frozen unevenly, the dough is inelastic, and the ice cream core melts or migrates. Tunnel blast freezers can eradicate both issues using forced cold air—typically from -35°C to -45°C—to retain freshness, maintain shape, and prevent textural flaws.

Following removal from the forming machine, the second operation would be the tunnel freezer. Frozen products are then palletized and ready for cold storage with minimal handling to avoid the risk of contamination and labor cost.

2. Tunnel Blast Freezer Types Used for Mochi Ice Cream

Although all tunnel blast freezers can rapidly chill mochi ice cream products to subfreezing temperatures, the choice of a specific machine type will significantly affect performance, energy consumption, footprint, and final product quality. Here is a complete description of the most common types of tunnel blast freezers utilized for the production of mochi ice cream on a factory scale:

1) Linear Tunnel Freezers (Straight-Through Belt Type)

This is the most common arrangement in mochi ice cream production plants. Product is conveyed linearly along a stainless steel mesh or modular plastic conveyor belt through an extended insulated pipe, where high-velocity cold air is blown over the product from top, bottom, or both.

Key Benefits:

- Allows high-throughput production (5,000–30,000 pcs/hr).

- Multiple zones of freezing allow progressive temperature decreases to avoid surface cracking or expansion of the fill.

- Gentle integration with upstream forming lines and downstream packaging automation.

Ideal Application:

High-volume mochi factories with steady SKUs and around-the-clock shifts.

2) Modular Tunnel Freezers

Assembled in prefabricated, plug-in modules, modular tunnel freezers provide phased factory flexibility. Each module may feature its own cooling source, fan units, and control panel.

Key Benefits:

- Expandable: Easily expands from a 3-meter to 9+ meter freezing length with expanding production.

- Low disruption of production during installation.

- Reduces capital exposure of new entrants or expanding brands.

Ideal Application:

Accommodates planning growth in the long term, peak seasons in manufacturing, or phased automation investment.

3) Compact Tunnel Freezers (Tabletop or Pilot Plant Models)

The mini tunnel freezers are best employed in R&D, test kitchens, or specialty mochi manufacturers. They have the same freezing principle but at smaller capacities (typically 200–800 pieces/hour).

Key Benefits:

- Easy to install and clean in a hurry.

- Suitable for small-sized rooms or test labs.

- Optimum for making new flavors, shapes, or mochi shell types.

Ideal Application:

Pilot lines, specialty mochi manufacturing facilities, or R&D departments in big plants.

4) Cryogenic Tunnel Freezers (Liquid Nitrogen or CO₂)

This equipment uses cryogenic gas in liquid nitrogen (-196°C) or carbon dioxide form that immediately freezes the mochi ice cream upon coming into contact with it. Products pass through a tunnel where cold vapor flows around them directly.

Key Benefits:

- Ultra-high-speed freezing with texture, shape, and flavor retention.

- Prevents ice crystal growth and surface destruction.

- Low profile, ideal for tight floor spaces.

Limitations:

- Higher operating costs through cryogen usage.

- Requires rigorous safety procedures for gas handling.

Ideal Application:

High-end or premium mochi SKUs, gluten-free or soft-shell SKUs, and operations where appearance perfection and sensory superiority are essential.

5) Hybrid Tunnel Freezers (Mechanical + Cryogenic)

These freezers combine traditional air-blast mechanical refrigeration with pre-freeze or after-freeze by cryogenic. As an example, the crust may be rapidly quenched with nitrogen and then mechanically deep-core frozen.

Key Benefits:

- Freeze curve control prevents cracking or deformation of the mochi shell.

- Better mouthfeel and chewiness control.

- Less material stress in packaging with uniform interior temperature.

Ideal Application:

Multi-SKU factories must have keen textural control over a wide variety of product ranges or export-quality manufacture with low defect threshold.

6) Comparison of Freezer Types

| Freezer Type | Throughput | Footprint | Cost (CapEx/OpEx) | Use Case |

|---|---|---|---|---|

| Linear Tunnel | High | Long | Moderate/Moderate | High-speed mass production |

| Modular Tunnel | Medium–High | Scalable | Flexible/Future-saving | Expansion-ready plants |

| Compact Tunnel | Low | Very Small | Low/Low | R&D or niche/batch producers |

| Cryogenic Tunnel | Medium | Compact | Low/High | Delicate, premium, fast-changeover setups |

| Hybrid Tunnel | Medium–High | Medium | High/Moderate | Texture-critical or high-end international SKUs |

3. How Tunnel Freezing Maximizes Cold Chain Logistics?

Off the production line, tunnel blast freezers play a strategic role in providing end-to-end cold chain from post-process warehousing to far-flung distribution. Flash and continuous freezing guarantee the stability of mochi ice cream not just within the factory, but throughout the logistics chain as well.

- Enhanced Product Stability: With fast sequestration of water and structure, freezing of the tunnels avoids degradation of the texture during storage or transportation. Fast freezing of mochi minimizes the chances of freezer burn and shrinkage even under temperature fluctuation during shipment.

- Packaging Conditions Optimized: Frozen portions of mochi are also easy to manipulate when neatly packed. Since products, having the nature of being dry and friable at the surface, turn non-sticky upon tunnel freezing, products will neither stick to packaging nor to one another, reducing wastage due to deformation and improving appearance.

- Extended Shelf Life: Low temperature retards enzymatic conversion and microbial growth. Well packaging can subsequently increase mochi shelf life to weeks, even months, a convenient feature to transport to overseas countries.

- Automation Compatibility: Tunnel-freezing is downstream compatible with automatic packing machines, refrigerated storage, or automated palletizers. Having such integration at the end avoids downtime and maintains the frozen chain.

- Logistics Case Example: A major Southeast Asian manufacturer of mochi substituted tunnel blast freezers for batch-type spiral freezers. It saw a 30% decrease in cold storage rejections after installation on the merits of improved temperature uniformity and a 20% decrease in late export shipments on the basis of faster pack-out times.

In simple terms, a tunnel blast freezer is worth far more than front-end freezing—these machines are an excellent point at which to initiate the cold chain that secures mochi quality all the way through to the last hand of a consumer.

4. The Benefits of Mochi Ice Cream Tunnel Blast Freezer Modular Expansion

When the companies grow, factory locations also have to grow. Freezers that provide blast-free tunnel space allow long-term expansion through modular build, process improvement, and operation redundancy.

1) Planning for Throughput

When designing a mochi plant, capacity balance is not today’s problem but tomorrow’s. A tunnel freezer will be selected, keeping tomorrow’s volume expansion in view. For example, doubling the present 1,000 mochi/hour line within two years. Modular or expandable equipment avoids future replacement at great cost.

2) Modular Expansion in Practice

Most recently installed tunnel freezers are built in increments. An initial section can begin as a 3-meter tunnel and subsequently be extended to 6 or 9 meters by adding additional sections. By doing this, capacity is added without shutdown or plant redesign.

3) Redundancy and Risk Management

The other units have redundant parallel lines as well. The other unit can be overloaded anytime when a specific freezer is under maintenance. It is particularly helpful in the event of peak hour or the addition of new items.

4) Cost Efficiency Over Time

Though the tunnel freezers have a high upfront cost, their operating efficiencies—fewer personnel, less product loss, and quicker freezing—are commensurate with true cost savings. With a 3 to 5 year payback, most companies achieve total ROI, especially including modular increments over purchasing entirely new systems.

5) Multi-SKU Custom Solutions

With new packaging sizes, shapes, or flavors, flexibility is necessary. There are certain multi-belt or double-belt tunnel freezers that can be used to handle more than one SKU on a single line without individual lines.

It’s smart planning, not big equipment. With the right tunnel blast freezer strategy, businesses can expand with greater confidence, less disruption, and more production.

5. How to Choose the Right Tunnel Blast Freezer for Your Mochi Ice Cream Line?

Choosing the right tunnel freezer is critical to sustaining product quality, process efficiency in production, and the scalability of the business. Let us break it down step by step to ensure you receive the best investment:

Step 1: Identify Your Production Rate

- < 1,000 pcs/hr → Compact or Cryogenic models

- 1,000–10,000 pcs/hr → Linear or Modular systems

- 10,000 pcs/hr → Linear or spiral types with high velocity and automation

Step 2: Assess Floor Space and Layout

- Do you need a lot of straight line space (10–15m)?

- Are you space-constrained vertically or with limited space (use spiral or modular)?

- Will you need to expand at all? If so, use modular configurations.

Step 3: Assess Product Variety

- Multiple SKUs = Need for multi-zone controls and rapid changeover functions

- High-value or fragile products = Consider cryogenic freezing

- Blended production (mochi/snack/ice cream) = Choose hybrid systems

Step 4: Compatibility with Upstream & Downstream Equipment

- Be compatible with installed encrusting machines, flour dusters, packaging units, and palletizers.

- Consider suppliers that offer integrated production solutions.

Step 5: Compare Energy and Maintenance Costs

- Verify energy efficiency ratings (e.g., insulation, VFD control).

- Ask about spare part availability, warranty conditions, and remote support capability.

Step 6: Get a Good Supplier

Choose manufacturers with:

- Custom configuration options

- Installation & operator training

- International approvals

- Post-sale support & remote diagnostics

6. Mochi Ice Cream Tunnel Blast Freezers FAQs

1) What is the average time to freeze mochi ice cream in a tunnel blast freezer?

Frozen time is generally 8 to 15 minutes, depending on product size, thickness of shell, and setpoints (usually −35°C to −45°C). Cryogenic systems reduce this to under 5 minutes.

2) How do I choose between a cryogenic and a mechanical tunnel freezer?

Choose mechanical freezers for economy and high-line volumes. Cryogenic freezers are best utilized on high-value products with ultra-fast crust freezing to preserve texture and appearance.

3) Is the same tunnel blast freezer applicable for multiple mochi SKUs?

Yes. Most units feature digital recipe control, multi-zone temperature control, and variable belt speed, allowing for easy flavor changeover, size, and shape.

4) How much installation space does it require?

Depending on the model. A standard linear tunnel freezer may use 8–15 meters of line space. Modular and spiral designs minimize footprint for small production areas.

5) Will it integrate with my existing forming and packaging machines?

Most freezers nowadays are built with standard interface points and integrate well with upstream encrusting equipment and downstream flow wrappers, robotic pickers, or tray loaders.

6) What service is necessary to achieve peak performance?

Regular cleaning of the routine, weekly belt and fan cleaning, and monthly full system calibration. Some even have self-diagnosis and remote monitoring to make the process easier.

7) What does a tunnel freezer consume in terms of energy?

Power consumption of 20–60 kW/h based on size and mode of operation. Cost-saving types with VFD fan controls and insulated walls can be bought to minimize costs.

8) When can the investment be recovered?

For most manufacturers of medium to large size, 3-5 years are needed to realize ROI, mainly from labor savings, reduced product loss, and greater throughput.

7. Conclusion

The mochi ice cream tunnel freezer blender is more than just a freezer; It’s the go-to for high-volume, high-quality production. From accommodating delicate textures to its influence on shipping and packaging, this machine delivers consistent value down the supply chain at every turn.

By having an idea of what type of tunnel freezers you are purchasing, and how much downstream operations and future growth they will affect, manufacturers can make financial decisions that will position their companies in the future. Regardless of what you start out with or choose modular expansion for global distribution, a quality tunnel blast freezer will have your mochi product up, and over industry standards.