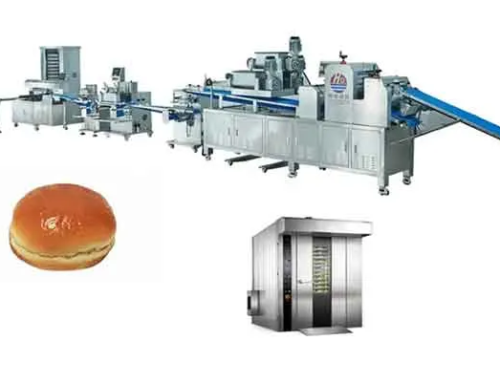

Automating croissant production is no longer a luxury reserved for mega-bakeries—it’s the fastest route to consistent quality, lower unit cost, and safer, more hygienic operations. This guide walks through how modern croissant lines work, what modules you actually need, the metrics that matter, and how to scale capacity without sacrificing lamination quality. Real-world specs from the SFT-NJX-640S Automatic Croissant Moulding & Rolling Machine are included for context.

1. Why automate croissants?

Croissants are deceptively complex. A perfect honeycomb crumb and flaky crust depend on repeatable dough rheology, precise butter-to-dough layering, accurate cutting, and gentle curling. Manual variance at any step—sheet thickness, butter plasticity, proof time—shows up on the shelf as uneven volume or collapsed layers. Automated lines reduce these variances with servo-driven settings, recipe libraries, and in-line monitoring (weight, dimensions, and temperature), typically pushing first-pass yield above 98% when the line is set up correctly.

2. The typical process flow

Although layouts vary by brand and plant size, most lines follow this sequence:

- Dough make-up & buffering

Dough is mixed and rested to relax gluten. A small buffer conveyor evens out feed into the line. - Sheeting & gauging

A series of gauge rollers reduce the dough to a precise thickness without overworking it. Closed-loop feedback keeps thickness constant as temperature and dough strength drift during the shift. - Butter (or fat) lamination

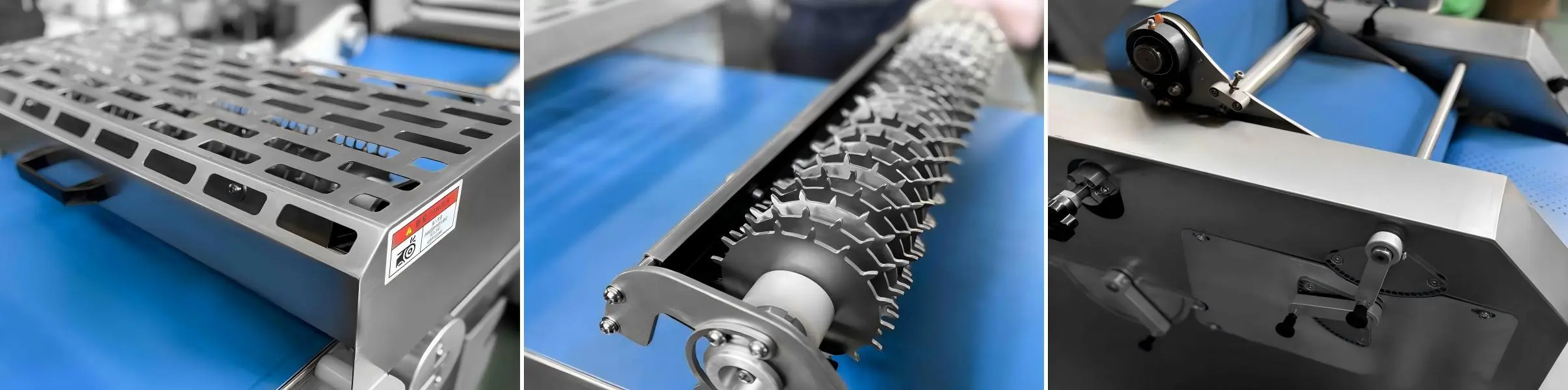

Butter is sheeted or extruded as a continuous slab and laminated with the dough sheet. Typical targets range from 16 to 64 layers depending on product (standard croissant, Danish, or premium “all-butter” lines). Temperature control (usually 12–16 °C butter, 16–20 °C dough) prevents smearing. - Cross-cutting & shape cutting

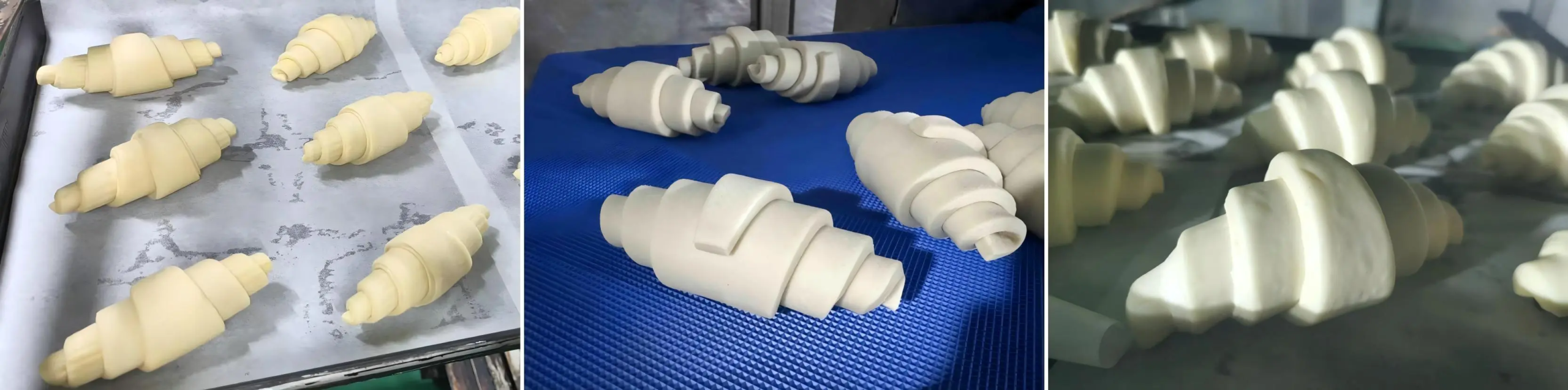

The laminated sheet is squared, then cut into triangles for croissants or alternative shapes for Danish products. Quick-change tools allow fast switchovers between triangles, hexagons, rings, and specialty patterns. - Curling & pre-shaping

Curling units roll the triangle without crushing layers. Servo control and adjustable finger pressure help maintain uniform length and tightness. - Depositing & spacing

Pieces are spaced on trays or band conveyors. Vision systems (optional) can reject off-spec pieces automatically. - Proofing

Controlled chambers (often 27–30 °C, 75–85% RH) allow yeast activity to create volume without melting butter. - Baking or freezing

Lines may feed directly to tunnel ovens for fully baked croissants, or to spiral freezers for ready-to-bake or par-baked SKUs. Cooling and packaging follow.

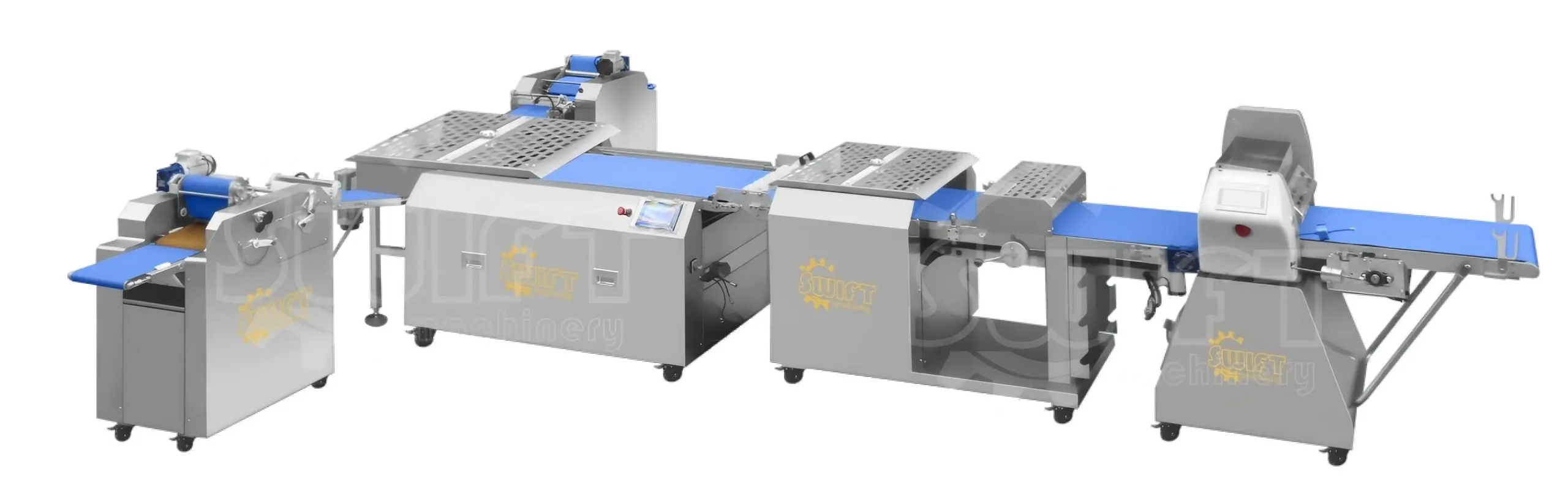

3. Spotlight: SFT-NJX-640S Moulding & Rolling Machine

For mid-to-large bakeries, the SFT-NJX-640S is a cost-effective forming core that slots into a modular line for croissants, Danishes, croissant “donuts,” and ginger bread pastries.

Highlights:

- Application: Commercial production of croissants and Danish-style pastries; multiple shapes via quick-change cutters.

- Line sections: Dough homogenizing, cutting, separating, and dropping; one distributor system plus tworolling/moulding units for throughput and shape stability.

- Precision: Tight weight control and a reported finished-product pass rate > 98%under proper setup.

- Shape flexibility: Triangles, hexagons, ring-shapes, and quincunx patterns for creative Danish SKUs.

- Changeover: Rapid tool swaps minimize downtime during product transitions.

Core specifications (SFT-NJX-640S)

- Conveyor belt width: 640 mm

- Capacity: 4,000–9,000 pieces/hour (dependent on size and proof/bake strategy)

- Power: 8 kW

- Voltage: 3-phase, 380 V

- Dimension: 6500 × 5300 × 1300 mm

- Weight: ~1000 kg

These specs place the machine squarely in the “industrial compact” class: wide enough for multi-lane production, yet small enough to fit existing rooms with limited ceiling height or constrained traffic aisles.

4. Common product formats

- Classic butter croissant: 55–75 g baked weight, 27–32 layers, straight or curved.

- Mini croissant: 20–35 g; often frozen ready-to-bake for foodservice.

- Pain au chocolat / Danish: Requires alternate cutters and folding routines; same lamination stack, different final shape.

- Innovations: Filled croissants (cream, hazelnut, cheese), croissant “donuts” (laminated ring), and savory SKUs (ham/cheese). Quick-change tooling is the enabler.

5. Scaling capacity: practical layouts

- L-shape vs. U-shape: An L-shape line with proofing on the long leg is space-efficient and simplifies operator flow; U-shape reduces travel distance between forming and packing.

- Two-lane strategy: On a 640 mm band, dual lanes of triangles allow higher throughput without increasing bake band width downstream.

- Buffering: Add short accumulation between cutting and curling to absorb micro-stoppages at the packer or tray loader.

6. Utilities, safety, and hygiene

- Electrical: Stable 3-phase 380 V supply and clean grounding for sensitive servo drives.

- Air & vacuum: Compressed air for actuators and quick-change locks; optional vacuum for precise pick-and-place.

- Sanitation: Daily dry clean of flour zones; scheduled wet wash for fat-contact areas with validated procedures. Tool-free belt removal and hinged hoods cut changeover time.

- Safety: Interlocked doors and guarded chains. Train operators on safe clearing of jams and lock-out/tag-out (LOTO) for sanitation.

7. Data, control, and continuous improvement

Modern lines store recipes (roller gaps, belt speeds, cutter timing, curl pressure) and can export production data. Track:

- OEE(availability, performance, quality)

- Waste by cause(cutting trim, start-up rejects, proof collapse)

- Weight & dimension trends

- Sanitation compliance time

Small tweaks—like tightening dough temperature bands or revising proof humidity settings—often unlock several points of yield.

8. Conclusion

An automated croissant line is a system, not just a machine. The SFT-NJX-640S-class former provides a strong forming core—640 mm band, 4,000–9,000 pcs/h, quick-change tooling, and >98% first-pass yield under control—while the surrounding modules (lamination, proofing, baking/freezing, and packing) complete the picture. Focus on layer integrity, weight control, and sanitation-friendly design, and you’ll get repeatable, premium product at industrial efficiency.