With the pace of the commercial bakery industry, scalability, consistency, and efficiency are the success mantras. Automatic bread-making machines have been the bread and butter of the new firm, enabling factories and foodservice chains to produce thousands of loaves a day with little or no human involvement. Whether expanding bakery products to your current business or beginning your business from the ground up, it’s in your best interest to be knowledgeable about the ingredients, process flow, and buying parameters for them. That’s what this comprehensive guide delivers: a step-by-step overview of the entire account on industrial bread maker machines, from operation and categories through daily use and advice on suppliers.

1. What Is an Industrial Bread Maker Machine?

An industrial bread maker is a machine used to produce bread in large quantities for large food processing factories. A home bread maker would produce a single loaf per batch, while an industrial bread maker would produce thousands of loaves of bread per hour. Industrial bread makers will mix, ferment, shape, bake, and package bread—all part of a continuous, optimized process.

Their primary purpose is to optimize efficiency, consistency, and scalability for commercial baking production. Commercial bread makers are the typical machines used in bakeries that offer supermarket chains, foodservice distributors, hotel chains, and quick-service restaurants. They reduce manual work, eliminate human mistakes, and maintain food safety regulations.

2. Types of Industrial Bread Maker Machines

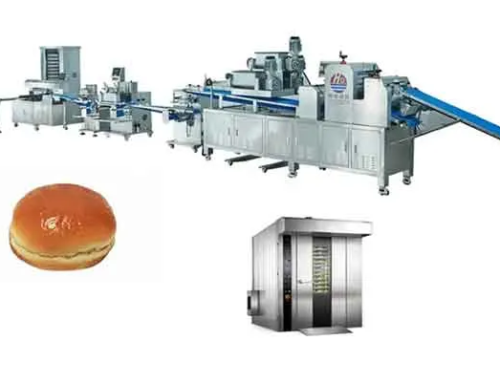

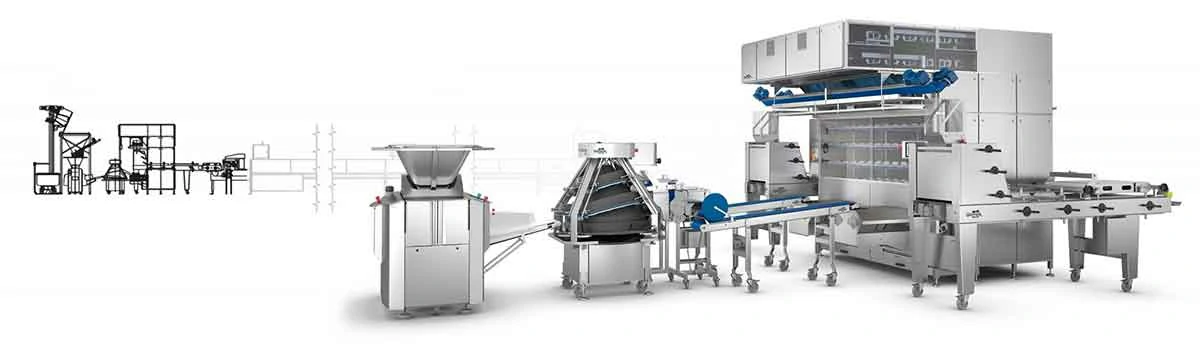

An industrial bread line will be a succession of machines performing various operations. Description of key units is below:

- Dough Mixers: These blend ingredients such as flour, water, yeast, salt, and oil. Spiral mixers are best suited for bread dough since they have a kneading action that is not harsh on gluten structure. Horizontal mixers deal with large amounts.

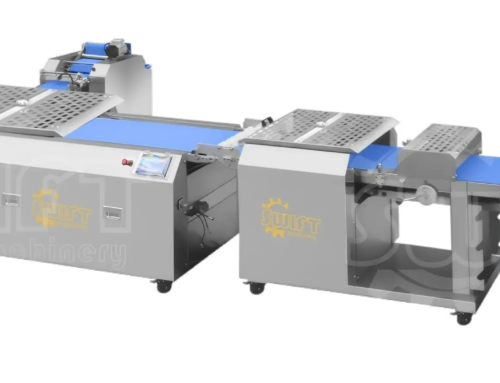

- Dough Dividers and Rounders: Dough is divided on weight or volume controls following mixing. The portion is rounded to supply even fermentation and to prevent air pockets from forming.

- Dough Proofer: Proofers offer a warm, humid environment that activates yeast and causes the dough to rise. Commercial proofers can be tiered rooms with programmable temperature, humidity, and timing controls.

- Bread Molding Machines: These give the dough its ultimate shape. They come in different mold shapes, so sandwich loaves, hot dog buns, or artisan bread are possible.

- Ovens (Tunnel / Deck / Rotary): Industrial ovens bake the dough evenly. Tunnel ovens consist of conveyor belts and are ideal for high-speed baking lines. Deck ovens offer more artisan crusts. Rotary ovens work best with batch baking and space-saving configurations.

- Cooling Systems: The bread is cooled before packaging in a way that forms condensation. Space savings and room air control are offered by cooling conveyors or spiral coolers.

- Slicing and Packaging Machines: The finished product is handled by the machine, slicing the loaves to uniform thicknesses and later packaging them into protective covering with date coding and labels.

All of the parts can be constructed to provide the shape, volume, and product size requirements of the bakery.

3. What is an Industrial Bread Making Line?

Industrial bread line demonstrates cause-and-effect, a sequential process with continuous manufacture:

- Ingredient Mixing: Ingredients are fed into the mixer by weight. Consistent dough consistency is provided by rate control and mixing time control.

- Resting and Pre-Fermentation (optional): The dough is rested to enable gluten development and the fortification of flavor in some processes. This may be achieved in resting troughs or tanks.

- Dividing and Rounding: The dough is cut into round, even-smooth balls or cylindrical forms. Intermediate proofing is included in the dough relaxation after rounding in some lines.

- Proofing: Proofing rooms are regulated with controlled heat and humidity,y where the dough will rise. This is done for 30 minutes to over an hour, depending on the recipe.

- Molding and Panning: The dough is shaped and put in pans or trays. Automatic pan greasing by some machines ensures it does not stick.

- Final Proofing: Second proofing allows the dough to achieve the highest volume prior to baking.

- Baking: Bread is processed through the oven under baking time and temperature control. Tunnel gas- or electricity-fired ovens are most commonly utilized.

- Cooling: Baked loaves are processed through ambient or forced-air coolers. Adequate cooling ensures spoilage prevention and texture preservation.

- Slicing and Packaging: Bread may be sliced by high-speed slicers, subsequently cooled, and automatically packed in bags or film wrap with an expiration date.

The system facilitates repeat high-capacity production and product integrity protection.

4. Parameters to Be Considered on the Purchase of a Bread Maker Machine

When buying an industrial bread machine, companies should seek parameters that will be appropriate to their production needs and future expansion:

- Production Capacity: Choose machines whose capacity yield will be appropriate for your average demand. Capacity ranges from 1,000 to over 10,000 loaves per hour.

- Long-Lasting Materials: Food-grade material and stainless steel material should be used to prolong corrosion resistance under sanitary conditions.

- High-Tech Control Systems: PLC and HMI panel-ready machinery provide precise control of recipes, time, and temperature.

- “Simple” Design: Modular designs are easy to add on when the business grows. Third-party equipment integration is also easier.

- Sanitation and Cleaning: Include CIP (Clean-In-Place) ability or tool-less removal for routine cleaning. Crevice-free and smooth surfaces reduce contamination hazards.

- Energy Consumption: Insulating ovens and energy-efficient motors save considerable amounts on operational expenses in the long term.

- Safety Features: Thermostatically controlled cut-off switches, emergency stops, and door interlocks provide operator and product protection.

All of these features equate to reliability, sanitation, and productivity in the long term.

5. Applications and Bread Types

Industrial bread machine equipment is multifaceted and adaptable to a wide range of business models and production needs. They are utilized in National chains and regional supermarkets, commercial bakery operations on a high volume.

Examples include Flowers Foods or Grupo Bimbo, in which automated lines at high speed produce one thousand bread pieces per hour. Centralized food preparation facilities and chain hotel kitchens (e.g., Marriott, Hilton), cruise ship foodservice (e.g., Royal Caribbean), airline foodservice (e.g., Emirates catering), and hospital foodservice, where consistent high-volume bread production is required.

Pre-formed dough and part-baked bread wholesalers like Rich Products or Dawn Foods distribute pre-formed dough and part-baked bread to chain QSRs like Subway, McDonald’s, and Starbucks. Private label or OEM bread manufacturing contract manufacturing plants that manufacture private label or OEM bread for grocery stores, convenience stores, or food distributors. For instance, a contract bakery manufactures private label lines of bread for Whole Foods Market or ALDI.

Institutional and restaurant catering businesses with canteens provided in corporations, schools, or military barracks, where the industrial bakeries have control over manufacturing and standardization. Artisan bread producers are replicating hand-prepared European-style or sourdough recipes at industrial levels with programmable automation to have control over the crust texture and the quality of the crumb, but on a larger scale.

In-store bakeries or in-store bakery cafes within retail megastores like Walmart, Costco, or Carrefour that require semi-automatic or modular bread machine units for in-store daily production.

The units are designed for use in the production of a wide range of types of bread products, including:

- White and whole wheat sandwich loaves

- Sub rolls, hamburger buns, and hot dog buns

- Multigrain and rye bread

- Rustic sourdough and artisan-style loaves

- Ciabatta, focaccia, naan, and flatbreads

- Sweet breads, raisin loaves, milk bread, and brioche

Industrial machines with changeable molds, multi-zone proofing, steam injection baking, and real-time recipe management can accommodate an unknown number of regional and market-specific bread products. With such versatility in producing custom-designed products, manufacturers can satisfy diverse consumer tastes in retail, foodservice, hospitality, and institutional markets.

6. Benefits of Using Industrial Bread Maker Machines

Running industrial bread-making equipment involves operational and economic advantages:

- Speed and Efficiency: Automatic baking has much shorter cycle times than hand baking, thus enabling firms to ship enormous orders on time.

- Consistency: Machines offer precise temperature, weight, and timing control, ensuring that each loaf of bread is the same, has the same size and the same texture.

- Labor Optimization: Avoids over dependence upon trained bakers and minimizes the risk of human mistakes, simpler training, and less variable labor costs.

- Recipe Flexibility: The recipe is stored, altered, and revamped easily to accommodate shifting dietary seasons as well as product line changes.

- Compliance: New equipment is designed for compliance with food safety standards such as CE, UL, GMP, and HACCP.

- Return on Investment (ROI): Although the cost of investment is greater in the short term, cost savings in the longer term on labor, wastage, and energy make it worth the investment.

Automatic bread lines are an essential piece of machinery in the food industry today due to these advantages.

7. What are the Tips for Selecting the Right Bread Maker Machine for Your Business?

Selecting the right industrial bread maker machine is a business choice that will have an impact on your productivity level, product range, and cost base in the future. Below are the main considerations to consider seriously:

1) Level of Production: Start with your current output day and month levels and add anticipated growth. A 1,000-per-hour bread machine will be ideal for a community bakery and will not be adequate for a factory producing for national chains, where a line must produce 10,000+ per hour.

2) Bread and Product Flexibility: Check to see if you need to make multiple types of bread products (loaves, buns, artisan shapes). Programmable control and flexible mold machines simplify changing product formats. Some models will handle gluten-free or high-hydration doughs.

3) Floor Area and Space Available and Floor Plan: Quantify available plant floor area, ceiling space, and the availability of utilities (gas lines, electricity, water). Add space-efficient or modular configurations in line with your floor plan, with future expansion space.

4) Level of Automation: Select fully automatic, semi-automatic, or hybrid configurations based on your workforce and your finances. Fully automatic lines are ideal for consistent high-output production, while semi-automatic equipment offers more hands-on activity and flexibility.

5) Power and Utility Demand: Decide on each machine’s power ratings, water consumption, and gas/electric heating loads. Make sure your plant support systems are capable of supporting them without incurring an expensive upgrade.

6) Ease of Operation and Maintenance: Choose equipment with simple controls (touch HMI screen, multilingual menus) and straightforward maintenance and cleaning, hygienic design. Ask about the normal maintenance procedure and cleaning time.

7) Supplier Reputation and Technical Support: Choose suppliers who have a reputable name and international certification (ISO, CE, UL). Ask if local service is available, training courses are available, backup by spare parts is available, and remote diagnostics can be performed.

8) Warranty and After-Sales: Compare response time, quantity of maintenance visits offered, and warranty duration. A long warranty, 24/7-supported can help avoid the monstrosities of cost and downtime in the future.

9) Return on Investment (ROI): Trade off total cost of ownership (equipment + installation + operation + maintenance) with the desired level of improvement in productivity, saving labor, and reproducibility of quality. Recipe memory equipment, energy-saving equipment, and less downtime have been proven to have a greater contribution to ROI.

10) Special Customization Needs: If proprietary recipes or special dough needs (extended fermentation, seeded doughs, etc.) are needed, seek out suppliers that offer custom options. Design consultation or test baking trials are offered by some.

Also, it is advisable to request demonstrations of equipment, visit installed equipment, and consult installed owners of installed models under consideration. Site research will be more instructive on actual performance and allow you to make an informed investment.

8. Major Manufacturers and World Trends

Several major industrial bread machine manufacturers produce professional equipment in a variety of sizes and applications:

- Rheon (Japan): High-precision filled product shaping machines and bread and pastry forming machines are their forte.

- Fritsch / Multivac (Germany): Well-engineered bakery equipment of good quality with modular designs that can cater to industrial and artisanal production.

- Baker Perkins (UK): Full bread-making systems for sliced sandwich bread and roll production.

- Sinmag and Sanko (Asia): Low cost and expanding overseas network, ideal for mid-scale production lines.

Trends to Watch:

- IoT and Smart Home Baking: Machines have also been linked to cloud-based systems for real-time monitoring, performance tracking, and predictive maintenance.

- Energy Efficiency: Energy recovery machines, low-emission machines, and environmental utilization of material are in great demand.

- Flexible Lines: Multi-product production and quick changeover are becoming the standard for bakeries producing seasonal or regionally demanded products.

Being tuned into these trends puts your bakery on the competitive radar and in line for expansion.

9. Conclusion

Choosing the right machine takes into account the requirement for production, available space, reliability of the supplier, and future expansion. The technology has advanced to the level that today there are more efficient, more automated, and power-saving industrial bread machines, so it’s a good investment for any bakery that wants to grow and be competitive in the current food industry. Regardless of whether you are launching a new plant bakery or increasing your production line, SFT bread-making machines can cater to the customers’ present and future business expansion in the market.