The croissant is a classic French puff pastry, known for its golden, crispy exterior and soft, airy interior. In France, croissants are a breakfast staple often paired with coffee or hot chocolate. Globally, the croissant has become a symbol of French baking, widely featured in cafes and bakeries.

In industrial croissant production, the most critical stages are lamination and shaping. These steps involve precisely folding layers of dough and butter to create the pastry’s signature flakiness and crescent form. The following sections detail these key processes, enhanced by cutting-edge technologies.

1. Lamination: Where Layers Are Born

Lamination is the essence of the croissant, the process responsible for its hundreds of delicate, buttery layers. It involves folding butter into dough repeatedly to create thin, alternating layers. During baking, the butter melts and releases steam, causing the dough to expand into flaky sheets—defining the croissant’s unique texture. This process demands meticulous control and consistency.

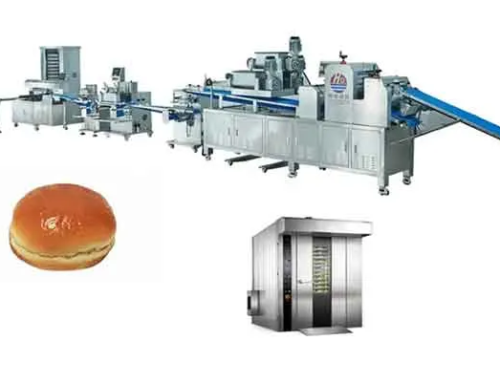

Shanghai Swift Machinery is a professional croissant machine manufacturer, offering automatic Croissant Frozen Pastry Dough Production Lines that ensure uniform butter-dough distribution and gentle handling throughout lamination.

Uniform Butter Distribution

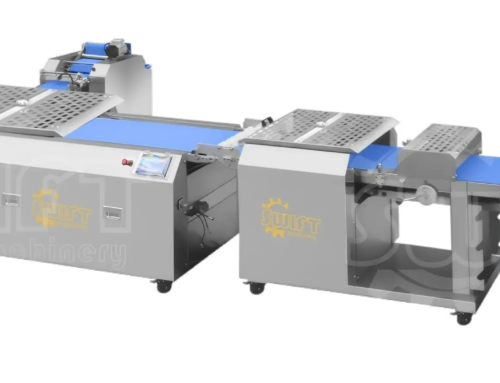

Achieving a croissant’s signature layered texture requires even thickness in both dough and butter prior to folding. Inconsistencies in frozen dough thickness can affect baking results and texture. Our equipment, equipped with intelligent control systems, guarantees consistent dough thickness—improving quality and minimizing waste.

Gentle Dough Handling

Controlling mechanical stress is essential to maintain gluten networks, which are crucial for proper layer separation and volume. Excessive stress can lead to dense, poorly layered croissants. The Automatic Danish Bread Frozen Pastry Dough Production Line from Shanghai Swift Machinery uses low-stress pressing systems that preserve the gluten structure, producing dough with a relaxed, uniform interior.

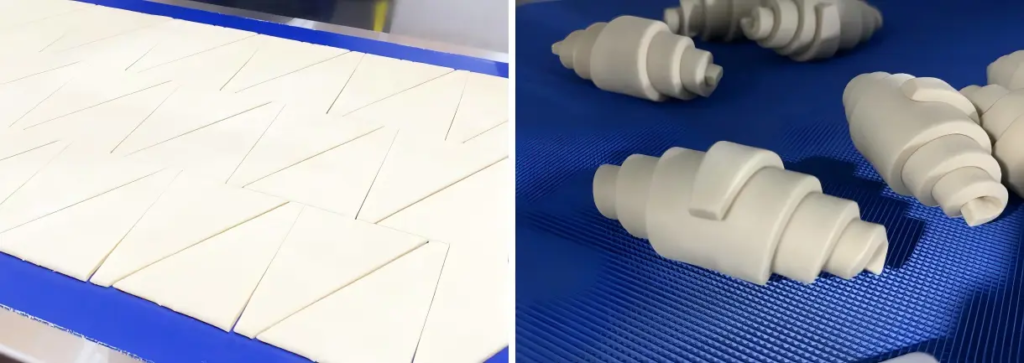

2. Cutting & Molding: Precision in Every Curl

After lamination, the dough is cut into triangular segments and rolled into crescent shapes. This step determines the croissant’s final weight, shape, and visual appeal.

The Automatic Croissant Molding and Rolling Machine from Shanghai Swift Machinery features a streamlined, intelligent design. The production line consists of a dough cutting section, a separation mechanism, and dual rolling units. Laminated dough is first shaped into strips, cut into triangles, and separated automatically before being rolled into croissants.

Weight Accuracy

Equipped with advanced weight control systems, our molding machine ensures every croissant meets precise specifications. This consistency reduces manual labor and boosts productivity, maintaining high product standards.

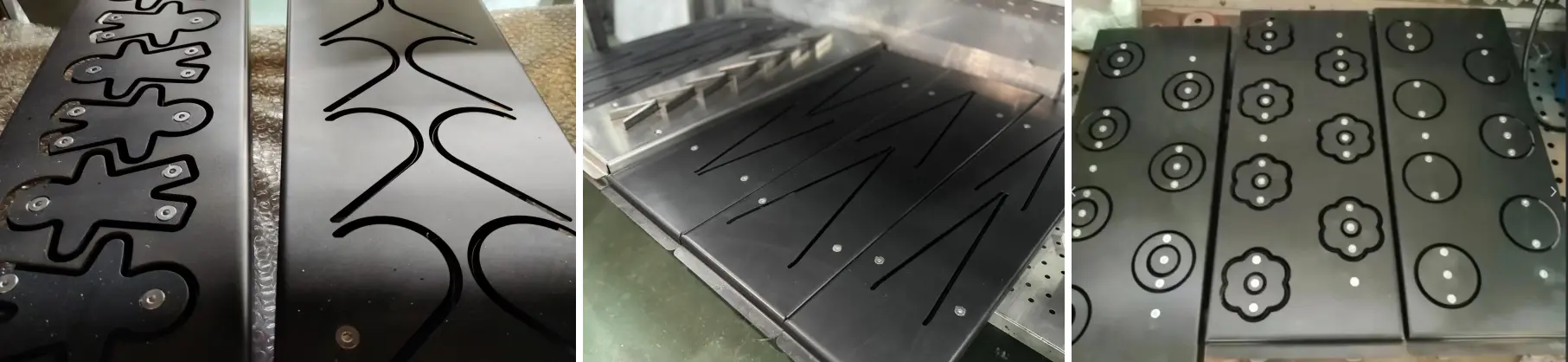

Diversified Production

With an easily interchangeable cutter, the machine supports production of various shapes including triangles, rings, and custom designs. Manufacturers can switch products efficiently while minimizing costs.

3. Conclusion

Perfect croissants are created through precision long before baking begins. Lamination and shaping are two vital steps that require engineering excellence. Shanghai Swift Machinery’s automated production lines combine traditional artisanal techniques with modern efficiency and scalability. For producers seeking quality, versatility, and performance, it’s time to invest in equipment that matches their ambitions.