If you sell, serve, or mass-produce siomai/shumai (also spelled shaomai, siew mai, or siu mai), a purpose-built shumai machine is the most reliable way to standardize quality and scale volume without ballooning labor costs. This guide walks you through how modern shumai machines work, what to look for when evaluating models, and how to match capacity and features to your production goals. It draws on proven practices in Chinese, Southeast Asian, and Japanese markets—where siomai is a high-velocity staple—and uses concrete data from three representative models in our SFT series: SFT-60, SFT-80, and SFT-880.

1. What exactly does a shumai machine do?

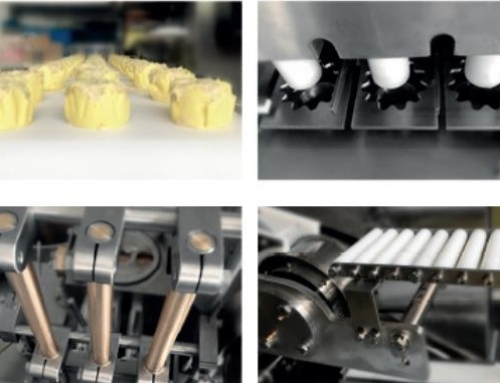

At its core, a shumai machine automates the repetitive, precision steps involved in forming a shumai: creating (or feeding) a dough sheet, thinning and pulling it to a constant gauge, cutting wrappers to size, dosing filling, forming / crimping, and transferring finished pieces to a takeaway conveyor for steaming or freezing.

Across the industry, the winning formula is:

- Consistent wrapper thickness→ even steaming, better bite.

- Accurate filling weight→ controlled food cost and nutrition labels.

- Stable forming and alignment→ trays load faster; packs look professional.

- Hygienic, cleanable construction→ compliance with food safety standards.

Most commercial machines accomplish this with a dough feed and belt-forming set, a pressure wheel (with independent speed control on higher-end models), precision cutters, a positive-displacement filling pump, a forming die, and an outfeed conveyor. Features such as auto-alignment, adjustable wrapper thickness, and tool-less disassembly make day-to-day operation both faster and safer.

2. Understanding the SFT lineup at a glance

We manufacture three complementary models that cover small pilot lines all the way to high-throughput central kitchens. Here are their headline specifications:

1) SFT-60 — Semi-automatic Double Row (Seaweed-wrapper friendly)

- Capacity:1,000–4,000 pcs/h

- Product weight:10–50 g

- Voltage:220V / 380V

- Rated power:5 kW

- Machine size:1550 × 1350 × 1850 mm

- Net weight:700 kg

- Notable features:Conveyor configured for round or square pieces; optional water-spray device to work with seaweed (nori) wrappers; food-grade stainless steel; compact footprint for quick disassembly and maintenance.

Best for: R&D kitchens, boutique restaurants, and brands launching seaweed-wrapped SKUs or mixed formats without committing to fully automatic tooling.

2) SFT-80 — Fully Automatic Double Line

- Capacity:5,000–6,000 pcs/h

- Product weight:10–85 g

- Voltage:220V / 380V

- Rated power:0 kW

- Machine size:1550 × 1350 × 1850 mm

- Net weight:900 kg

- Standout tech:Electromagnetic clutch enables independent speed regulation of the pressure wheel for stable belt tension; auto-alignment of shumai for neat rows; one-pass belt formation → thinning → pulling → cutting → filling → molding → conveyor transfer; all stainless steel & food-grade contact parts; designed for easy disassembly.

Best for: Busy restaurants, mid-size producers, commissaries making pork, shrimp, and mixed siomai; operators who value a compact machine with true single-pass automation.

3) SFT-880 — Fully Automatic Three Lines (High Output)

- Capacity:6,000–9,000 pcs/h

- Product weight:10–45 g

- Voltage:220V / 380V

- Rated power:5 kW

- Machine size:1950 × 1250 × 1900 mm

- Net weight:1,100 kg

- Enhanced capability:Three-lane production for Japanese shumai, Philippine siomai, Indonesia siomay, dim sum wonton-style, and Hawaiian pork hash; auto-alignment, independent pressure-wheel speed control, adjustable wrapper thickness and stuffing weight, and high-capacity uniform output—ideal for hotels, central kitchens, and food factories.

Best for: Scale-focused plants requiring consistent, high-speed output and lower unit labor costs.

3. Inside the mechanism: why these features matter

- Independent pressure-wheel speed (SFT-80/880).Dough stretching needs delicate control: too fast and the belt tears; too slow and you’ll over-thicken, causing uncooked centers. Electromagnetic clutch control lets you tune belt tension by product—thin Japanese shumai wrappers versus thicker, rustic siomay.

- Auto-alignment.Perfect rows reduce the time to rack or tray the pieces and minimize deformation during transfer. In larger plants this directly raises effective throughput because downstream staff no longer need to straighten products manually.

- Adjustable wrapper thickness & filling weight (SFT-880).This is the backbone of SKU standardization. You can run a 12 g shrimp shumai for convenience packs in the morning and switch to a 38 g pork hash for foodservice at lunch with only a few tool-less adjustments.

- Seaweed-wrapper option (SFT-60).Nori is unforgiving—too dry and it cracks, too wet and it slips. The optional water-spray stabilizes moisture so the sheet wraps neatly and seals consistently.

- Food-grade stainless design.Stainless steel frames and contact parts make daily sanitation faster and align with global HACCP/GMP best practices. Smooth surfaces and quick-release assemblies (no tight crevices) decrease risk of harborage.

4. Product formats you can run

Shumai has global aliases—siomai (Philippines), siomay (Indonesia), shaomai/shumai (China), shūmai (Japan)—and each region likes different sizes and textures. With the SFT series you can cover:

- Classic Cantonese pork & shrimp shumai(round or square wrappers).

- Philippine siomai(often garlic-forward, sometimes with carrots) in 15–30 g range.

- Indonesian siomay(firmer filling) and Japanese shūmai (smaller, delicate skins).

- Hawaiian pork hash

- Seaweed-wrapped SKUs(SFT-60 with spray).

For every SKU, match wrapper thickness and filling viscosity to forming stability. A general rule: higher shrimp ratios call for a slightly tighter, colder mix; pork-only recipes are more forgiving.

5. Installation, training, and sanitation

Site prep. Provide a stable, level floor, adequate space to access all four sides, and a dedicated 220/380 V line with proper grounding. Compressed air is not required for core functions on these models; check your accessory list if adding custom devices.

Commissioning & training. Operators should be confident in:

- Setting belt thickness and pressure-wheel speed.

- Calibrating filling weight (use a scale and count 20 pcs to average).

- Changing forming parts and cleaning contact components.

Cleaning routine (daily):

- Power off and lock out.

- Remove and soak contact parts in approved alkaline foam cleaner; brush and rinse.

- Wipe down frames and guards; avoid high-pressure jets on bearings and electrical panels.

- Sanitize and air-dry; reassemble with food-safe lubricant where specified.

Weekly/Monthly:

- Inspect belts for wear; check alignment marks.

- Verify electromagnetic clutch response and limit switch function.

- Audit fasteners and guarding; replace gaskets if hardened.

6. Quality & food safety

While regulations differ, the following best practices are widely accepted across China, Southeast Asia, the EU, and North America:

- Material compliance:Use food-grade stainless for all product-contact parts; keep a materials list on file for audits.

- Allergen control:If you run shellfish and non-shellfish SKUs, plan color-coded tools and validated changeover cleaning.

- Temperature control:Keep fillings at ≤4 °C (39 °F) until forming; steam or freeze promptly after discharge.

- Traceability:Stamp batch/lot codes right after forming; auto-aligned rows make vision counting and checkweighing easier.

Our SFT machines are designed to support these controls with smooth surfaces, quick-release assemblies, and stable one-pass processing that minimizes hand contact.

7. Frequently asked questions

Q1: Can these machines handle square wrappers?

A: Yes. The SFT-60’s conveyor can be set up for round or square products; SFT-80/880 accept standard forming sets for both geometries.

Q2: What about gluten-free or alternative wrappers?

A: Many customers run starch-blended skins. Start on the SFT-80/880 (for finer control of belt speed and thickness) and conduct trials to tune hydration and resting time.

Q3: What maintenance skills do we need in-house?

A: Basic mechanical aptitude is sufficient: belt tracking, fastener checks, lubrication of specified points, and replacement of wear parts like scrapers and seals. The design emphasizes tool-less disassembly to shorten sanitation and part swaps.

Q4: Do I need a different machine for Japanese vs. Cantonese shumai?

A: No. With thickness/weight adjustments and the right forming set, a single SFT-series machine can produce both.

8. Final checklist before you buy

- Define your top three SKUs(target weight, wrapper style, and desired hourly volume).

- Map your line layout(infeed of wrappers, outfeed to steaming/freezing, tray size).

- Verify utilities(220/380 V, dedicated circuit, space for sanitation).

- Decide on options: seaweed-spray kit (SFT-60), forming sets, spare belts, and alignment guides.

- Plan operator training and sanitation SOPsfrom day one.

9. Conclusion

Whether you’re a chef upgrading from hand-forming or a central kitchen looking to standardize across multiple brands, the SFT series delivers dependable capacity, clean design, and the right level of control:

- SFT-60for flexible semi-auto and seaweed wraps,

- SFT-80for compact, fully automatic double-line production, and

- SFT-880for high-throughput three-lane operations.

With accurate dosing, stable belt control, and hygiene-focused engineering, a modern shumai machine doesn’t just make more dumplings—it makes better dumplings at a repeatable cost. If you’d like a tailored capacity plan or a trial run on your recipes, share your target weights and daily volumes, and we’ll map the exact configuration that fits your kitchen.